Welcome to Daphal Industries

High Precision Components

Welcome to Daphal Industries. We have pleasure in introducing ourselves as a Leading Manufacturer of Heighly Precision Components . We specialize Manufacturing of CNC Soft & Hard Jaws, T-NUT, JAW Boring Fixtures, Other CNC Machine Components. Daphal Industries Established in 2017 is an ISO 9001:2015 certified company located at bhosari, Pune, India.

Daphal industries Manufactures chuck jaws for all styles of chucks be they of foreign or domestic manufacture, we can supply you quality jaws to fit any chuck, With greater emphasis placed on productivity to offset escalation of cost. You can totally rely on us for your work holding needs.

Should you require any additional information for your work - holding needs, feel free to call on us or write to us and we will recommend to you correct jaw style for your chucking operation. We also undertake to machine jaws as per customer drawing and specifications. We look forward to being of service to your organization.

Below are Our Range of Products:

1) SOFT JAW

2) Hard Jaw

3) T-NUT

4) JAW Boring Fixtures

5) FULL ENVELOPE CHUCK JAW SET

1) SOFT JAW

2) Hard Jaw

3) T-NUT

4) JAW Boring Fixtures

5) FULL ENVELOPE CHUCK JAW SET

Testing Equipment's in Machine Shop

1) Zero to 300 micro meters Metetued Make

2) 10 to 300mm board gauge Metetued Make

3) 600mm x 600mm surface table

4) Digital Height Gauge 300 mm

5) Dial Vernier zero to 300mm

6) Digital Vernier zero to 300mm

1) Zero to 300 micro meters Metetued Make

2) 10 to 300mm board gauge Metetued Make

3) 600mm x 600mm surface table

4) Digital Height Gauge 300 mm

5) Dial Vernier zero to 300mm

6) Digital Vernier zero to 300mm

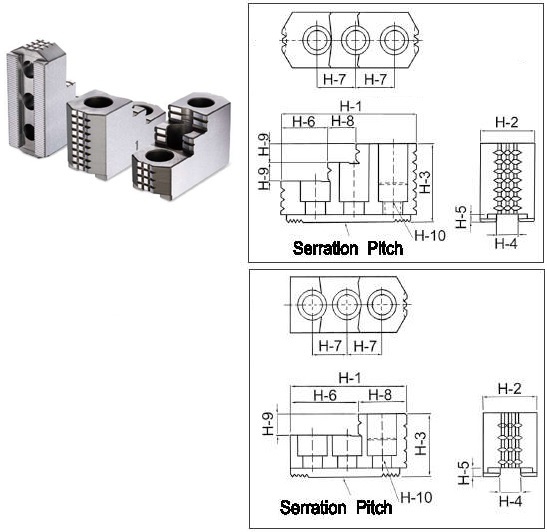

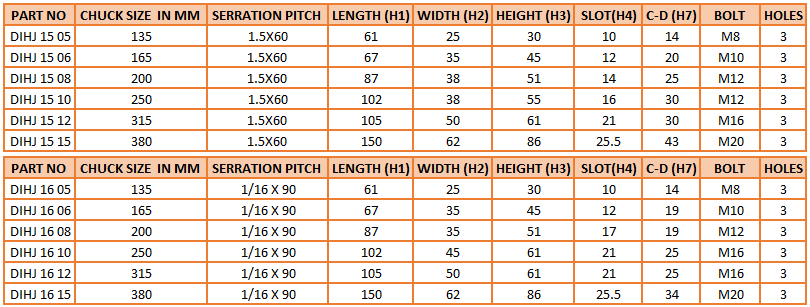

1) SOFT JAW

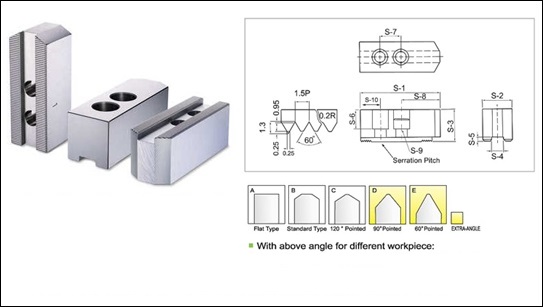

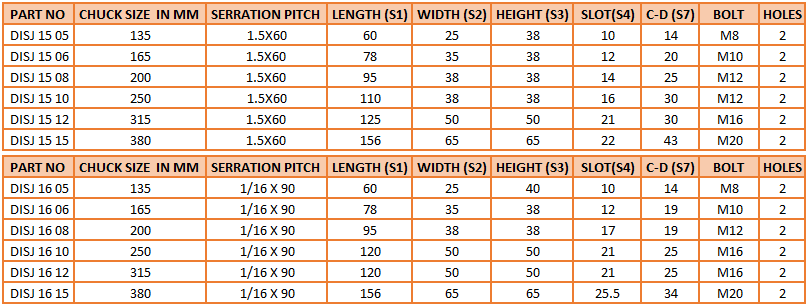

We Specialize in Manufacturing Soft JAW. The soft jaws - 1.5mm x 60 Degree or 1/16" x 90 degree - standard type is used in CNC lathe. According to different process term, customers can choose varied sizes and more convenient, and avoiding unnecessary correction movement. Available in steel(S45C).

We manufacture with different types of workpiece such as Flat type, Standard type 120 Degree pointed, 90 Degree pointed,

60 Degree pointed, Serration Pitch, 1.5mm x 60 Degree or 1/16" x 90 degree. To suit various types of chucks.

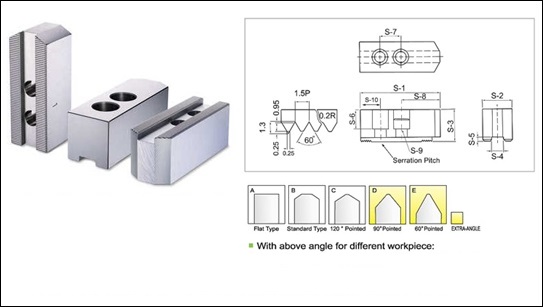

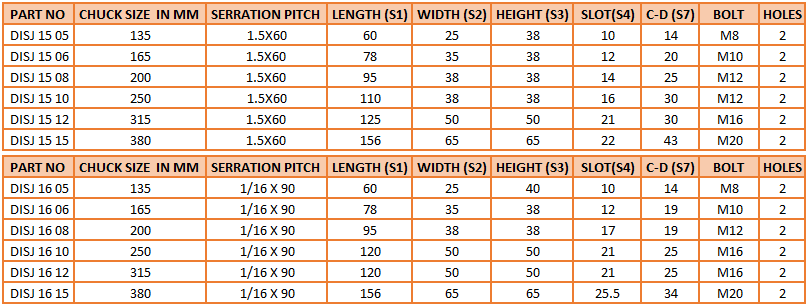

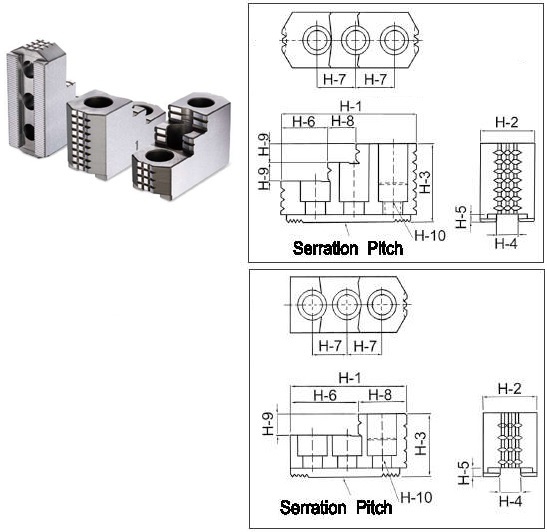

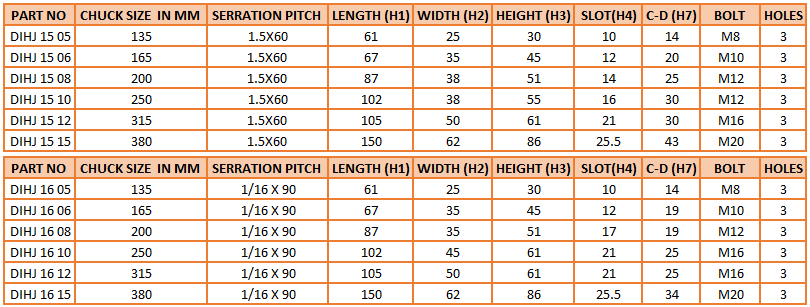

2) HARD JAW

We Specialize in Manufacturing Hard JAW. The hard jaws (HJ 10) are suitable for CNC lathe. The hardened serrations of

the clamping step are designed to clamp the workpiece securely without leaving large scrape.

The Hard jaws standard type is used in CNC lathe. According to different process term, customers can choose varied sizes and more convenient, and avoiding unnecessary correction movement. Available in steel(S45C).

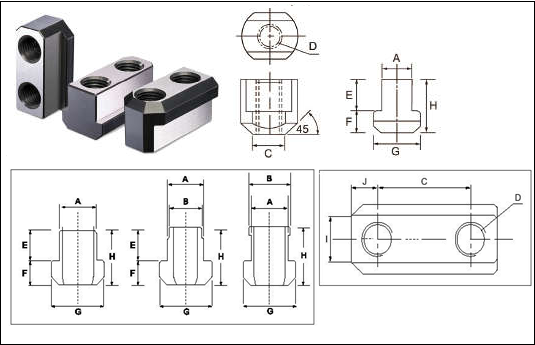

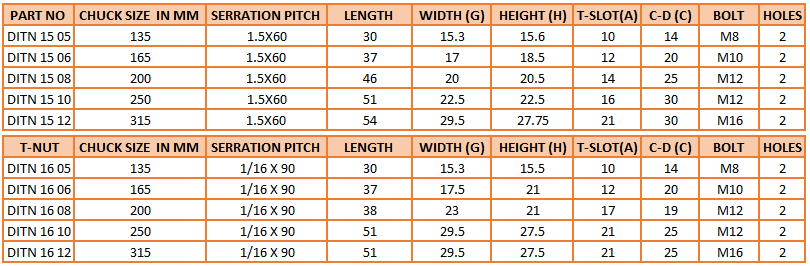

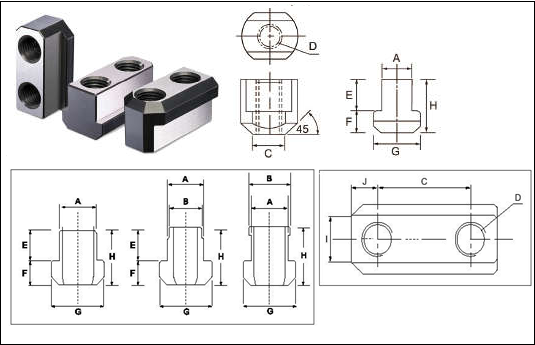

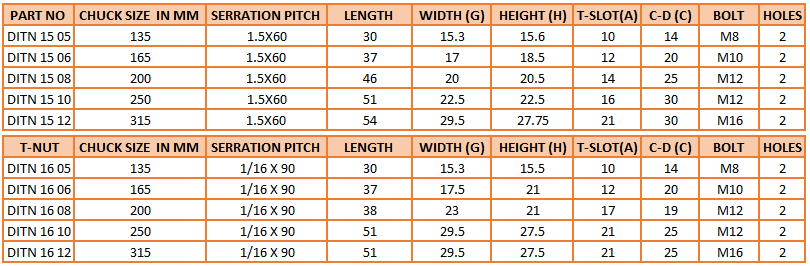

3) T-NUT

We Specialize in Manufacturing T-NUT. The jaw t-nuts (T08) are suitable for

various types of Chucks. The jaw t-nuts is connecting with power chuck and soft

jaws. It used Materials like SCM440. We categorize the T-nuts into Standard

type, Special type.

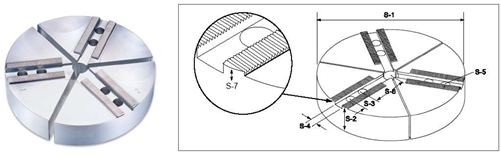

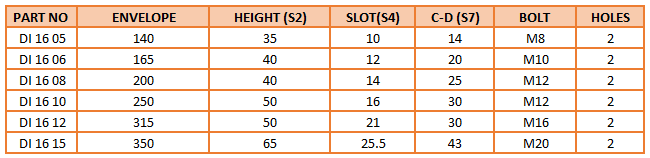

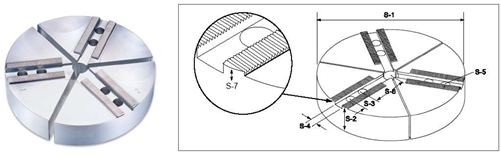

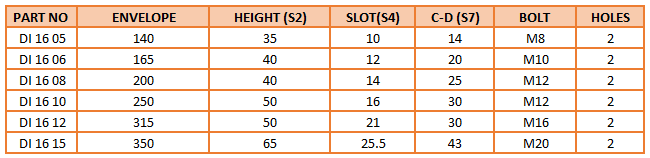

4) FULL ENVELOPE CHUCK JAW SET

We Specialize in Manufacturing FULL ENVELOPE CHUCK JAW SET. The aluminum round jaws are suitable for extra bigger outer dia. (thin pipe.).

This type of round jaws can cover the outer dia. of work piece enable to decrease deformation and increase the accuracy. The can hold parts with outer dia. of 200mm.

Its uses Materials Aluminum : 6061 T6. Serration Pitch 1.5mm x 60 Degree or 1/16" x 90 degree.

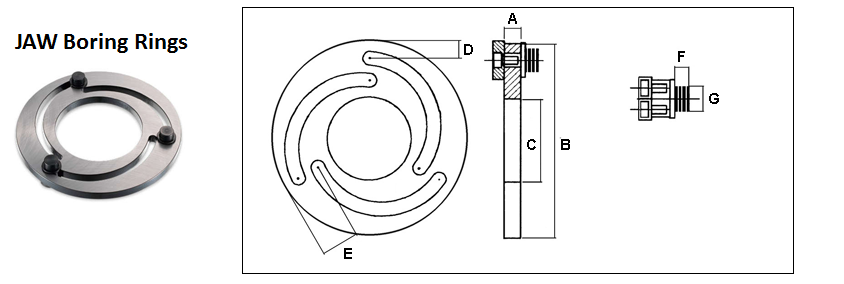

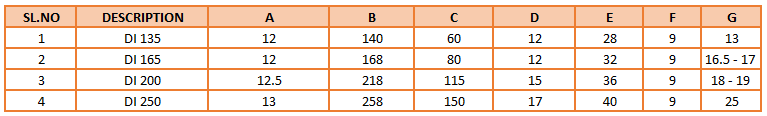

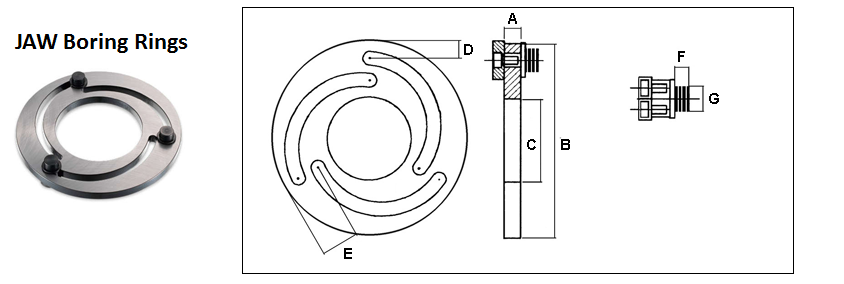

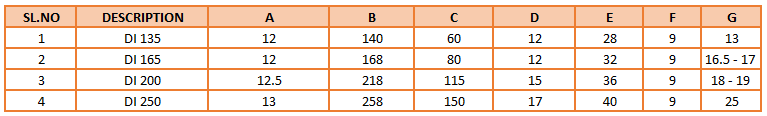

5) Jaw Boring Fixture

We Specialize in Manufacturing Jaw Boring Fixtures. There are various job boring fixtures such as JAW Boring ring, 3 Jaws Boring Fixtures.

The jaw boring fixtures (TL-type) is with a continuous micro adjustment is to provide accurate position, to reduce the abrasion of soft jaws.

Soft jaws can be made small sizes by this type easily, with only some simple process, soft jaws can be bored.

With anticlockwise lock, the machining field can be easily expended..

Disclaimer: All specifications are subjected to change without prior intimation. Please contact us for futher information.

Feel free to contact us for your any requirement.